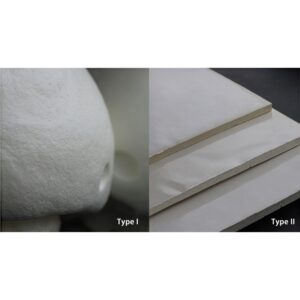

Phenolic Resin Foaming Material For Coal Mine Filling And Sealing

Phenolic resin foam material for coal mine filling and sealing has excellent flame retardant properties, high expansion ratio and low reaction temperature, and is particularly suitable for large volume filling.

Product Introduction

After uniform mixing of Component A and B of phenolic resin foaming material for filling and sealing in coal mine at 1:1 volume ratio, the material rapidly polymerizes into an insoluble and infusible polymer foam. This foam exhibits exceptional flame retardancy,

high expansion ratio, low reaction temperature, which is Ideal for large-volume filling.

Product Usage

Phenolic resin foaming material for filling and sealing in coal mine are widely used in cavity filling, roadway sealing, and other engineering applications in mining and tunnel construction. They provide air isolation, gas sealing, and structural reinforcement. Low-viscosity resin blends can rapidly permeate and diffuse into voids and cracks of varying sizes, then expand and solidify into the highly flame-retardant foam with an expansion ratio of 25–30× or higher.

Product Features

The insoluble and infusible polymer foam formed by uniformly mixing Component A and B of phenolic resin foaming material for filling and sealing in coal mine at the predetermined volume ratio exhibits the following characteristics:

- Complies with MT113-1995 standard requirements,Oxygen index>35%

- Excellent resistanceto solvents and corrosion

- Low internal reaction heat

- Low viscosity and high permeability:

- Effectiveanti-static performance

- Rapid and convenient construction

Physical and Chemical Properties

Item | Component A | Curing Agent |

Viscosity 25°C, mPa•s | <1000 | <100 |

Density,g/cm3 | 1.20±0.10 | 1.50±0.10 |

Color | Grey or Dark Brown | Yellow or Brown |

Physical Properties

Item | Specification |

Curing time | 5-10s |

Expansion Ratio | ≥25 |

Compressive strength,At 10% compressive strain,KPa | ≥10 |

Compressive strength,At 30% compressive strain,KPa | ≥10 |

Compressive strength,At 70% compressive strain,KPa | ≥40 |

Oxygen index,% | ≥35 |

Flame retardancy | Complies with MT 113-1995 |

Flame Propagation Test | Non-propagating flame |

Surface resistance,Ω | ≤3×108 |

Smoke toxicity index | ≤5 |

Note: The technical parameters herein are derived from laboratory testing and may deviate under actual application conditions. These values are provided for reference only and do not constitute legally binding obligations.

Usage Precautions

For the application of Phenolic resin foaming material for filling and sealing in coal mine, appropriate construction equipment should be selected, including mixing pumps and spray guns. Prior to construction, ensure calibration of the grouting equipment to verify the component mixing ratio and mixing pressure.

Before commencing formal construction, the buyer must conduct material reliability tests under conditions identical to the actual construction environment to verify the applicability of the composite materials.

Storage (Usage) Precautions

The composite material should be sealed and stored at room temperature (15°C to 20°C), well-ventilated, and shaded area. Avoid direct sunlight or long-term storage above 30°C, which may reduce foam performance.

Expiration Date

Under suitable storage conditions, the storage period of polyurethane material for consolidating coal and rock at coal mine is 3 months.

Safety Precautions

Direct contact with the material may cause moderate eye irritation and mild skin irritation, potentially leading to skin allergies. Repeated inhalation of high-concentration vapors can induce respiratory allergies. Immediate medical attention should be sought, and anti-inflammatory and anti-allergic symptomatic treatment measures should be administered.

During operation, exercise caution to prevent direct contact with skin or splashing into eyes. Wear necessary protective equipment (gloves, protective goggles, work clothes, etc.).

In case of skin or eye contact, rinse immediately with clean water for at least 15 minutes. Wash the skin with soapy water and seek medical attention if necessary. If accidentally ingested, seek immediate medical treatment for symptomatic management.

Fire and Explosion Hazards

This product is not classified as flammable liquids, explosives, oxidizers, corrosives, toxic substances, or radioactive hazardous materials during storage and transportation. It is not categorized as a hazardous product.

Carbon dioxide, foam, or chemical dry-powder fire extinguishers can be used. If no other fire-extinguishing agents are available, a large amount of water mist can be sprayed. Once the fire is extinguished, the spilled materials must be thoroughly cleaned (refer to the “Spill and Leakage Handling” section).

Fire-Fighting Procedure: Standard protective measures.

Spill and Leakage Handling

Small amounts of leaked or spilled materials can be rinsed away with water. In case of large-scale leakage, contain and recover the materials, and wash the contaminated ground with water or detergent. The disposal of waste composite materials must comply with the local government’s environmental protection regulations.

For more information, please refer to the Safety Data Sheet (SDS) of our products or contact our Customer Service Center.

The indicators and data provided in this document are based on our current level of technical knowledge and practical experience, and are for reference only. Specific guaranteed indicators are subject to the quality assurance certificate or supply contract. The user is responsible for testing the products purchased from our company to verify their suitability for their intended processes and applications, and to achieve the desired objectives. Further application and processing of our products are beyond our control. Therefore, our liability for the products provided is limited to the portion delivered by us and used by you. We do not assume responsibility for indirect losses incurred during the production process using our products as raw materials. Our technical support and customer service center are available to provide consultation and technical services related to our products. We welcome your inquiries and communication via mail or phone.

Contact Information

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

| Weight | 5485.71 kg |

|---|