In the tile laying of home decoration, traditional cement mortar easily causes tiles to hollow and fall off in the later stage, while tile back adhesive has become the mainstream choice due to its better bonding effect. The following details its usage methods, characteristics and misunderstandings.

1. Usage Methods of Tile Back Adhesive

- Stirring Treatment: Open the tile back adhesive. For example, Roskenning tile back adhesive has been fully stirred by machinery during production, and only needs to be gently stirred with a roller or brush.

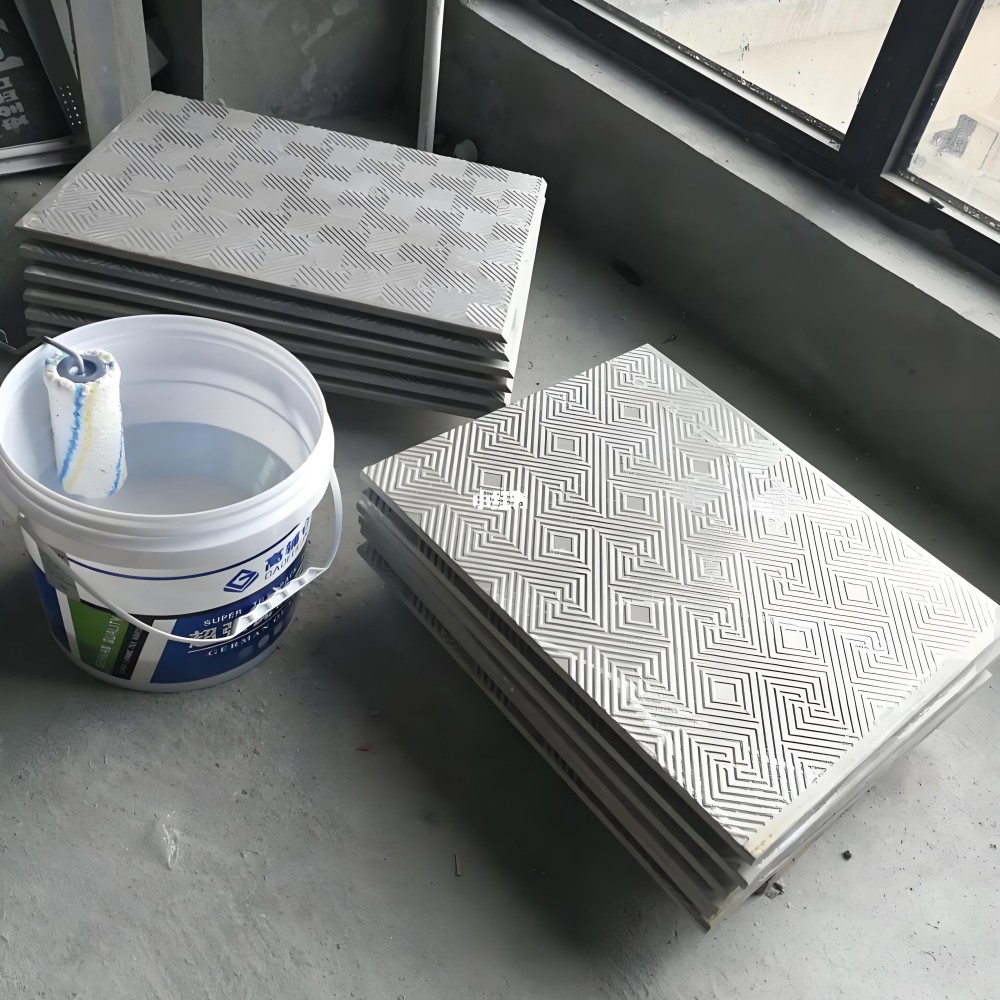

- Adhesive Coating on the Back: Small-sized tiles can be arranged and coated with a row brush; it is strictly forbidden to apply adhesive only on the two ends of the tiles. For large construction areas, a roller can be used for coating to ensure uniformity without missing any part.

- Tile Storage: After coating, the tiles should be placed upright against the wall separately, stored in a place free from sun and rain to prevent adhesion.

- Gap Leaving During Tile Laying: Use special plastic gap pads when laying tiles to ensure uniform gaps and avoid wall cracking and deformation due to temperature changes.

2. Characteristics of Tile Back Adhesive

- Strong Bonding Force: It can change the surface properties of objects, form a firm "bridge" between tiles and adhesives, improve the bonding force, and solve the problems of hollowing and falling off of vitrified tiles, etc.

- Long Service Life: It has good permeability, water resistance and weather resistance, and one construction can achieve both bonding and waterproof effects.

- Easy Construction: It can be applied directly on the back of tiles for operation.

- Non-toxic and Environmentally Friendly: It is made of environmentally friendly materials to ensure the safety of the indoor environment.

3. Six Common Misunderstandings in the Use of Tile Back Adhesive

- Changing the Liquid Proportion: The liquid proportion is determined through strict testing. Randomly changing it will reduce performance and cause tiles to be poorly bonded.

- Incorrect Coating Position: It must be evenly coated on the back of the tiles; the "cross method" is recommended to avoid missing coating and exposing the bottom.

- Not Treating Impurities on the Back of Tiles: Impurities such as dust and oil will form an isolation layer, reducing the bonding force and increasing the probability of hollowing.

- Reusing Remaining Material by Adding Water: The effective components of the remaining back adhesive have reacted. Adding water only changes the operational performance, resulting in insufficient bonding strength in the later stage.

- Adding Cement and Sand: It will change the component proportion of the back adhesive, affect the quality, and cause tiles to hollow and peel off.

- Random Construction in Winter: The construction temperature should be between 5-35℃. Construction below 5℃ is easy to cause freezing damage, and the newly constructed material should avoid water splashing within 24 hours; in summer, it is necessary to prevent exposure to the sun to avoid back adhesive failure and cracking.