In the field of modern building decoration, the reliability and durability of tile adhesion directly affect the aesthetics and service life of a space. The traditional tile adhesion method using cement and river sand often leads to problems such as hollowing, cracking, and even falling off of tiles due to insufficient adhesion and high shrinkage. However, Yantai tile adhesive, with its scientific formula design and excellent performance, has gradually become the mainstream material for tile adhesion. Its core advantages stem from the precisely matched functional additives and standardized proportioning and construction processes. Below is a detailed introduction from the aspects of composition, usage methods, and application advantages.

1. Core Components of Yantai Tile Adhesive: The "Synergistic Effect" of Functional Additives

Yantai tile adhesive is not a single-component material but a compound mixture of basic aggregates such as cement and quartz sand, combined with a variety of functional additives. Additives are the key to determining its performance; different additives undertake specific functions and jointly ensure the stability of tile adhesion.

1.1 Basic Functional Additives: Ensuring the Foundation of Adhesion and Construction

- Cellulose Ether: Known as the "water-retaining guardian" of tile adhesive, cellulose ether can form a three-dimensional network structure inside the mortar, effectively locking in moisture. This prevents the mortar from surface crusting and internal looseness due to rapid drying—a feature that is particularly important in dry environments (such as the heating season in northern China) or during large-area construction. It can avoid a decrease in adhesion caused by water loss, while also increasing the consistency of the mortar, making it smoother to apply during construction and reducing "sagging".

- Latex Powder: Referred to as the "adhesion enhancer" of tile adhesive, its main components include vinyl acetate/vinyl ester copolymer, vinyl laurate/ethylene/vinyl chloride copolymer, and acrylics. When exposed to water, latex powder gradually dissolves and forms an elastic film, which not only significantly improves the adhesion strength between the tile adhesive, tiles, and the base layer but also endows the material with good flexibility. When the building undergoes slight settlement or thermal expansion and contraction due to temperature changes, this flexibility can buffer stress and prevent tiles from cracking due to rigid pulling. Different types of latex powder are suitable for different scenarios: vinyl acetate/vinyl ester copolymer is suitable for ordinary indoor glazed tiles and full-body tiles; acrylic latex powder has better weather resistance and can be used for outdoor terraces, balconies, or damp bathrooms and kitchens to resist moisture erosion.

1.2 Special Functional Additives: Meeting Personalized Needs

To meet the special requirements of different construction scenarios, Yantai tile adhesive is additionally mixed with customized additives to further expand its application range:

- Wood Fiber: Its main functions are "crack resistance and extending working time". Wood fiber has good dispersibility and can be evenly filled inside the mortar, reducing shrinkage stress during drying and thereby lowering the risk of cracking in the mortar layer. At the same time, it can absorb part of the water and release it slowly, extending the "open time" (i.e., the workable time for construction) of the tile adhesive, making it easier for workers to adjust the position of tiles—especially suitable for novice construction or the adhesion of complex shapes.

- Modified Starch Ether: The key to solving the problem of "large-sized tile slippage". With the popularity of large-sized tiles (such as 600×1200mm, 800×800mm), traditional mortar is prone to sliding after tiling due to the self-weight of the tiles. Modified starch ether can improve the anti-sagging performance of the mortar. Even when applied to vertical walls or for tiling large tiles, it can firmly fix the position of the tiles and avoid problems such as "tile sagging and uneven joints".

- Early Strength Agent: Provides support for "projects with tight construction schedules". Early strength agents can accelerate the hydration reaction of cement, allowing the tile adhesive to increase its strength in a short time. For example, in scenarios with strict schedule requirements such as commercial decoration and old house renovation, tile adhesive with early strength agents can shorten the initial setting time to about 12 hours, meeting the needs of "quick access and quick delivery".

- Water Repellent Agent: Endows the tile adhesive with "waterproof properties". In areas that are in long-term contact with moisture, such as kitchens, bathrooms, and bathrooms, tile adhesive mixed with water repellent agents can form a hydrophobic film on the surface of the mortar, reducing water absorption, preventing moisture from penetrating into the base layer and causing wall dampness and mildew, and at the same time reducing the risk of tiles falling off due to water absorption and expansion.

2. Scientific Proportioning and Mixing: The "Key Step" Determining the Performance of Tile Adhesive

The performance of Yantai tile adhesive not only depends on high-quality components but also requires strict adherence to proportioning requirements and correct mixing methods—incorrect proportioning will directly lead to reduced adhesion, insufficient strength, or construction difficulties.

2.1 Precise Proportioning: The "Golden Ratio" of Powder to Water

The standard proportion of Yantai tile adhesive is powder: water = 1:0.25-0.3 (by weight), a ratio verified through numerous experiments:

- If there is too much water: It will dilute the concentration of additives such as latex powder, leading to a significant reduction in mortar strength. After drying, the shrinkage rate will increase, easily causing hollowing and cracking. At the same time, overly thin mortar has strong fluidity and is prone to sagging when applied to vertical walls, making it impossible to fix tiles.

- If there is too little water: The powder cannot be fully wetted, and lumps will form after mixing. There will be dry powder particles inside the mortar, which are prone to creating gaps during application, affecting the adhesion effect. Additionally, the construction feel will be stiff, making it difficult to spread evenly.

2.2 Standard Mixing: Allowing Additives to Fully 发挥 Their Effects

The core goal of mixing is to ensure uniform mixing of all components, especially the complete dissolution of additives. The specific steps are as follows:

- Prepare Tools: It is recommended to use an electric mixer (with a rotating speed of 500-800 rpm). Compared with manual mixing, it can achieve more thorough mixing and avoid lumping. If mixing manually, a hard rubber scraper should be used to ensure uniform mixing.

- Mixing Sequence: First, add the specified amount of clean water to the mixing bucket, then slowly pour in the powder while stirring—avoid pouring the powder first and then adding water, as this will cause the powder to clump and be difficult to break up.

- Mixing Time: Stir initially for 3-5 minutes until the mortar forms a uniform paste with no obvious particles. After stirring, let it stand for 1-2 minutes (called the "maturing time") to allow additives such as cellulose ether and latex powder to fully dissolve and form a stable structure. Then, perform secondary stirring for 1 minute. At this point, the mortar has the best workability, making it more conducive to construction.

3. Standard Construction Process and Post-Protection: Ensuring Long-Lasting Adhesion Effect

The correct construction method is the key to converting the performance of tile adhesive into actual adhesion effects, and attention should be paid to the application method, working time control, and post-setting protection.

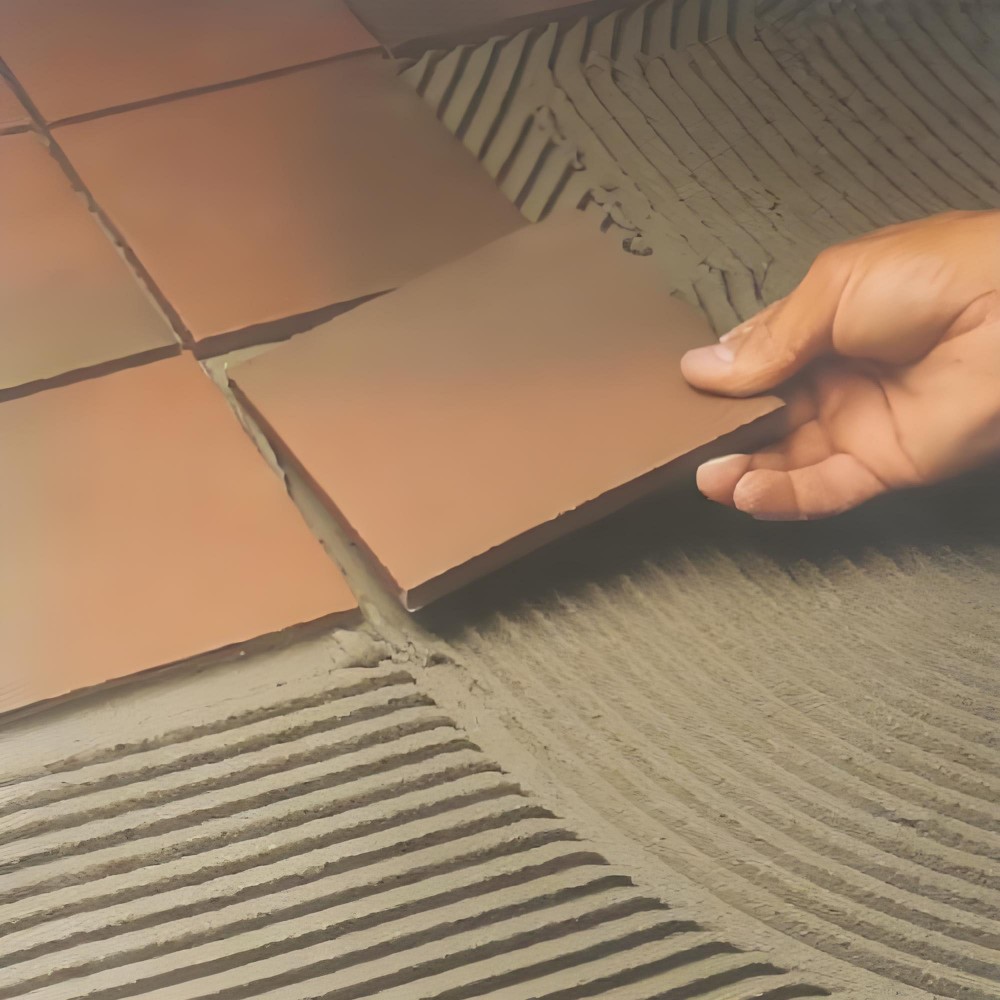

3.1 Key Points of Construction Operation

- Control of Application Thickness: Adjust the thickness according to the tile size—for ordinary small-sized tiles (such as 300×300mm), the application thickness is 3-5mm; for large-sized tiles (such as 600×1200mm and above), the "thin-set method" is recommended, with the application thickness controlled at 2-3mm. At the same time, apply a thin layer (about 1mm, called "back coating") on the back of the tile. This can eliminate air holes on the back of the tile, allowing the tile to fully adhere to the mortar, significantly improving the adhesion strength and avoiding hollowing.

- Workable Time: After the tile adhesive is mixed, construction must be completed within the "open time", which is usually 2-4 hours (specifically adjusted according to the environment: when the temperature is above 30℃ and the humidity is below 40%, the open time will be shortened to 1.5-2 hours, and the construction rhythm needs to be accelerated; when the temperature is below 5℃, it is recommended to take thermal insulation measures to prevent the mortar from freezing). Within the open time, the position of the tiles can be adjusted at any time to ensure neat joints; if the open time is exceeded, the mortar has initially set and cannot be mixed with water for reuse, otherwise, the internal structure will be damaged, leading to a decrease in strength.

3.2 Setting and Post-Treatment

- Setting Time: After the tile adhesive is applied, the initial setting time is approximately 24 hours, at which point grouting can be carried out; however, complete curing takes 7 days (the "curing period"). During the curing period, heavy loads (such as furniture handling and frequent treading) should be avoided, especially for floor tiles, to prevent tile displacement or cracking of the mortar layer.

- Grouting Requirements: When grouting, a grout compatible with the tile adhesive (such as cement-based grout) should be selected. Acidic grouts (such as epoxy grout, whose compatibility needs to be confirmed) should be avoided to prevent chemical reactions from corroding the tile adhesive and affecting the adhesion effect. Before grouting, dust and debris in the tile joints should be cleaned to ensure the grout is fully filled.

4. Core Advantages of Yantai Tile Adhesive: Why Replace Traditional Materials?

Compared with the traditional cement and river sand adhesion method, Yantai tile adhesive has significant advantages:

- Stronger Adhesion: The addition of latex powder makes the adhesion strength 2-3 times that of traditional materials, effectively avoiding hollowing and falling off—especially suitable for the adhesion of large-sized and heavy tiles (such as marble tiles).

- High Construction Efficiency: There is no need to soak tiles in advance like with cement and river sand. Moreover, the mortar has good workability and can be applied evenly, saving more than 30% of construction time.

- Low Shrinkage Rate: Additives such as wood fiber and latex powder can inhibit shrinkage, reduce the risk of cracking, and make the tiles flatter and more durable after tiling.

- Environmental Protection and Safety: It uses environmentally friendly additives and does not contain harmful substances such as formaldehyde and benzene, complying with national environmental standards for indoor decorative materials and ensuring residential health.

- Wide Application Range: By adjusting additives, it can be adapted to various scenarios such as indoor and outdoor areas, dry and wet areas, and low-temperature environments, meeting different decoration needs.

The above is detailed knowledge about Yantai tile adhesive, covering its composition, proportioning, construction, and advantages. It is hoped to provide practical references for decoration construction. If you need to learn more about the selection guide for different types of tile adhesive, solutions to common construction problems, and other content, please continue to pay attention to our website to obtain the latest industry information and technical support!