During the tile laying construction process, the correct use and subsequent protection of tile back adhesive play a crucial role in the laying quality. Many novice workers often make mistakes in the use of back adhesive due to lack of experience, especially ignoring the dust-proof protection of the back adhesive after brushing, which leaves hidden dangers for subsequent construction.

Tile back adhesive, especially one-component back adhesive, needs a certain period of time to dry after brushing, and this drying stage is precisely the critical period when it is most likely to get dusty. In a construction site environment, dust usually floats around. If protection is not done well, dust can easily adhere to the surface of the back adhesive that has not yet fully cured. Many workers find the protection steps cumbersome and skip this step directly when the construction period is tight and manpower is in short supply, but they do not know that this approach will seriously affect the subsequent construction effect.

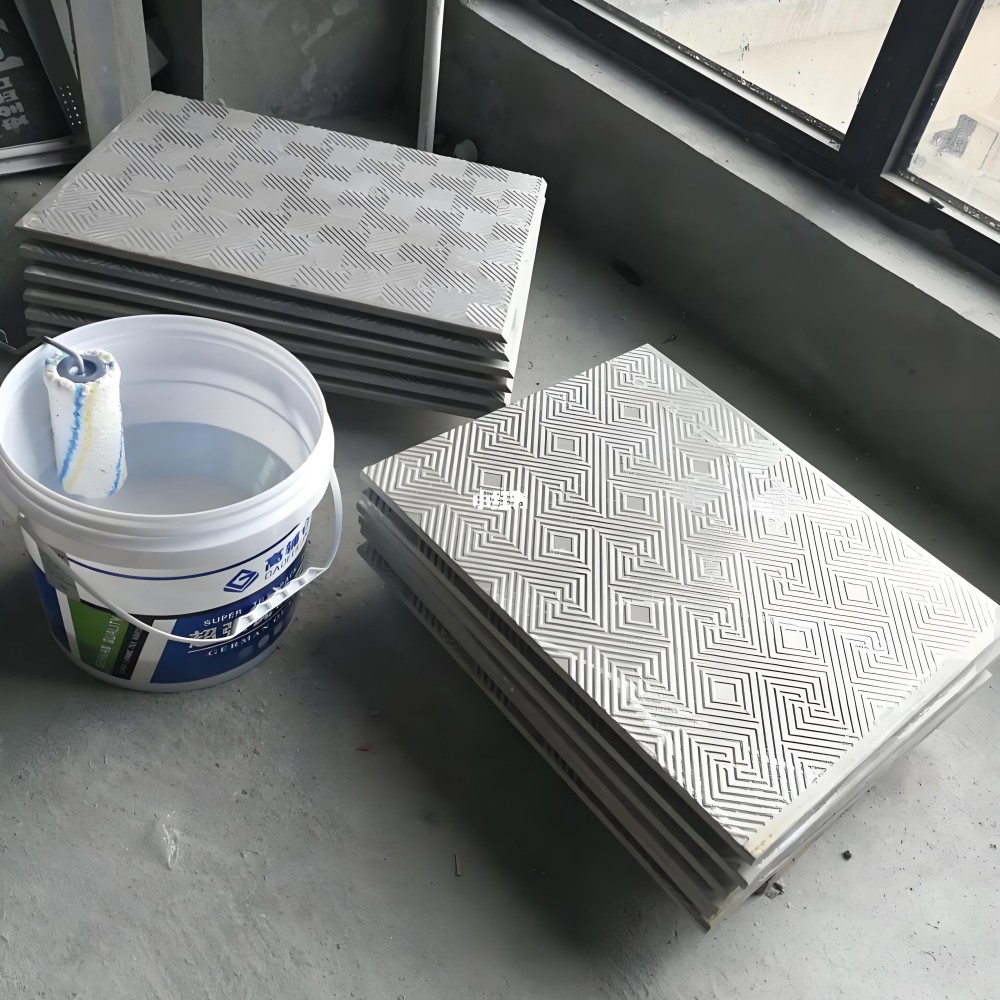

So, how to do a good job in protection during the construction of tile back adhesive? Firstly, protective measures must not be omitted and must be strictly implemented. Waterproof and dust-proof covering materials, such as plastic films and waterproof cloths, can be used to properly cover the tiles with brushed back adhesive to prevent direct contact with dust. Secondly, obvious protective signs should be placed around the protected area, clearly marked with words such as "No Touching" and "Under Construction" to remind other personnel on the construction site to pay attention and prevent accidental collisions or stepping that may invalidate the protective measures and affect the drying effect of the back adhesive.

If the brushed back adhesive accidentally gets dusty, how to deal with it? It should be noted that once the back adhesive is contaminated with dust, the dust will form an isolation layer between the back adhesive and the tile adhesive to be applied later. This isolation layer will greatly weaken the bonding force between the back adhesive and the tile adhesive, which may further lead to quality problems such as hollowing and falling off of the tiles after laying. Therefore, after getting dusty, it must be properly handled before proceeding with the subsequent tile adhesive construction.

When there is little dust on the surface of the back adhesive, the treatment is relatively simple. Prepare a clean and soft towel, dip it in a small amount of clean water, and note that the amount of water should not be too much to avoid excessive water penetration affecting the performance of the back adhesive. Then gently wipe the dust on the surface of the back adhesive with the damp towel. The movement should be gentle and slow to prevent damage to the back adhesive due to excessive force. After wiping, it is essential to wait for the back adhesive to dry completely, and confirm that there is no residual water or dust on the surface before proceeding with the next step of tile adhesive construction.

However, if the back adhesive is seriously dusty, with a large amount of dust adhering and difficult to wipe off with clean water, the situation is more tricky. In this case, even if you try to wipe it forcibly, it may not be possible to completely remove the dust, or the structure and performance of the back adhesive may be damaged during the wiping process. There will still be a risk of insecure bonding when laying tiles later. To ensure the quality and safety of tile laying and avoid troubles such as rework later, this batch of tiles with serious dust may need to be discarded, and tiles with well-brushed back adhesive and proper protection should be prepared again for construction.

It can be seen that in the process of using tile back adhesive, choosing the right tile back adhesive is the foundation, and using the right back adhesive and doing a good job in subsequent protection are the keys. At the same time, tile back adhesive manufacturers also give professional suggestions: after the tiles are rolled with back adhesive and dried, it is recommended to carry out the subsequent construction operations in time within 72 hours. This can better ensure the bonding effect of the back adhesive, guarantee the quality of tile laying construction, and reduce problems caused by improper construction timing or inadequate protection.