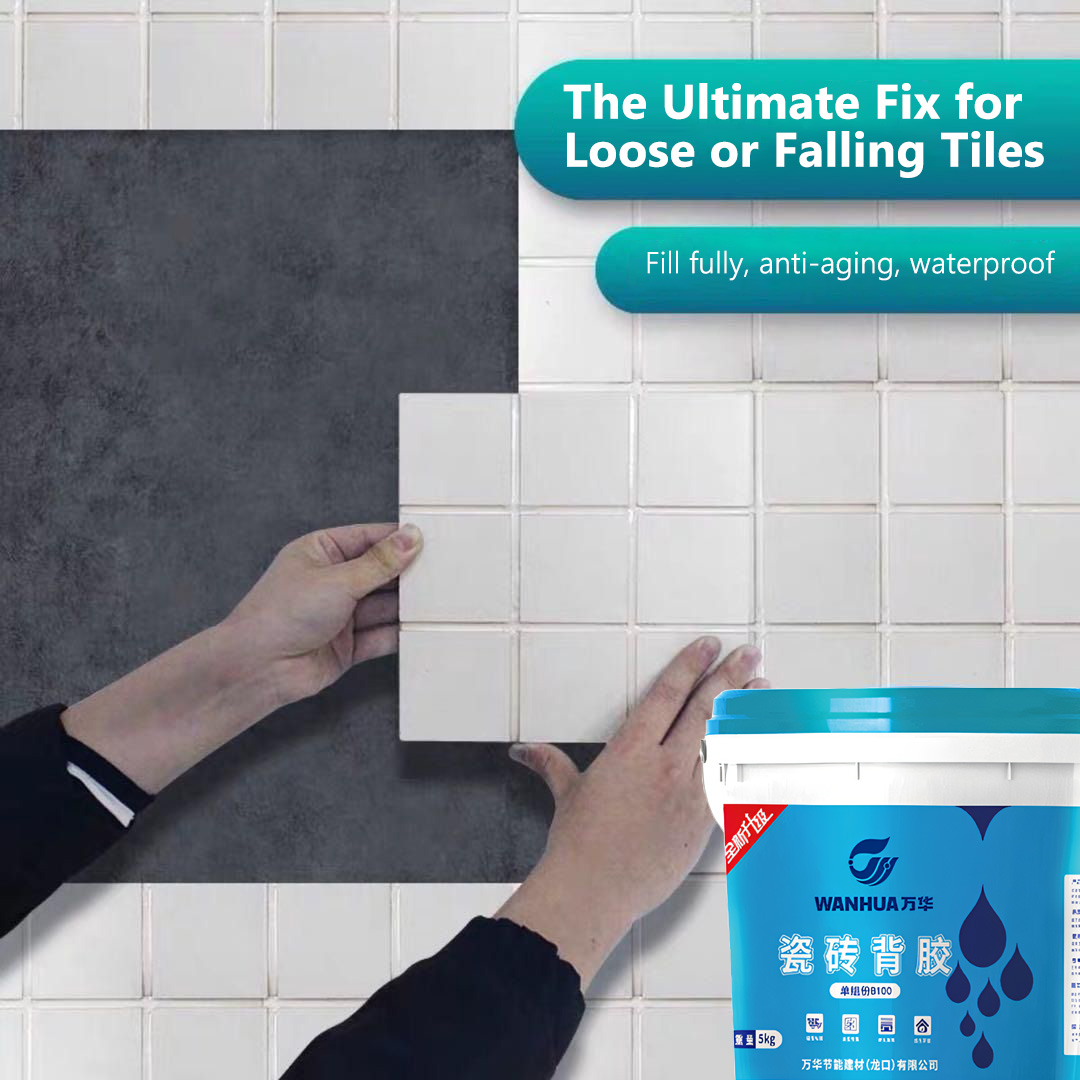

In the field of architectural decoration, the firmness of ceramic tile adhesion directly affects the overall decoration quality and service life. As a key material for the back treatment of wet-pasted vitrified tiles, the correct use of ceramic tile back adhesive is crucial. Ceramic tile back adhesive is carefully compounded from high-quality polymer emulsion materials and inorganic silicates. It can effectively improve the bonding strength between vitrified tiles and bonding materials, fundamentally solving the common problems of hollowing and falling off in the wet pasting of vitrified tiles. It can be used in combination with a variety of bonding materials to form a stable and reliable ceramic tile bonding system. When applied on standard concrete slabs and glazed tiles, it performs excellently, greatly improving the safety performance of ceramic tile bonding, so it is widely used in various decoration scenarios. However, in the actual construction process, many operators often fall into various misunderstandings due to their lack of understanding of the usage specifications of ceramic tile back adhesive, resulting in poor bonding effects and potential hidden dangers for subsequent use. Below, we will introduce in detail several major misunderstandings that need to be avoided in the use of ceramic tile back adhesive.

Misunderstanding 1: Randomly changing the ratio between liquids

The liquid ratio of ceramic tile back adhesive is not set arbitrarily, but determined by the manufacturer through numerous strict scientific tests and experimental screenings. This ratio enables the back adhesive to achieve the best bonding effect, ensuring that each component fully exerts its function and forms a stable bonding structure. In actual construction, some operators arbitrarily increase or decrease the liquid ratio for convenience or based on subjective experience. This practice will seriously damage the component balance inside the back adhesive, leading to a significant reduction in the bonding performance and weather resistance of the ceramic tile back adhesive. Using back adhesive with an improper ratio to paste ceramic tiles can easily lead to weak bonding between the tiles and the base layer. In the later stage, the tiles may become loose, hollow, or even fall off, which not only affects the decoration appearance but also may cause safety accidents and increase maintenance costs and difficulties.

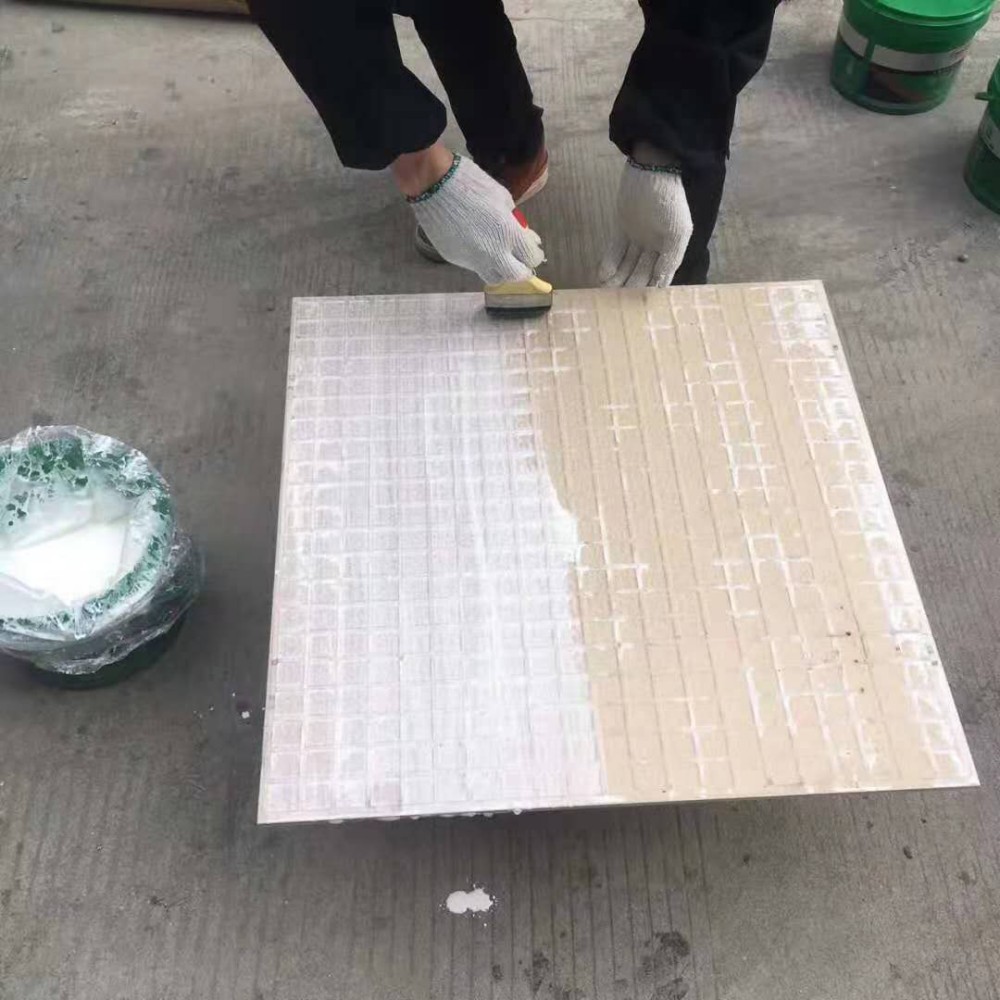

Misunderstanding 2: Ignoring the correct application position of ceramic tile back adhesive

The design purpose and working principle of ceramic tile back adhesive determine that it must be applied to the back of the ceramic tile, which is a key link to ensure the bonding effect. Only by using tools such as brushes and rollers to evenly apply the well-stirred back adhesive to the back of the facing tile can the mortar fully contact the back of the ceramic tile and form a tight bonding layer. During the application process, it is recommended to apply a uniform layer using the "cross method". This method can effectively avoid problems such as missing coating and bottom exposure, allowing the back adhesive to form a complete and uniform covering layer on the back of the ceramic tile. If the operator mistakenly applies the back adhesive to the surface of the base layer instead of the back of the ceramic tile, it will result in insufficient bonding area and inadequate contact between the back adhesive and the ceramic tile, failing to exert the bonding enhancement effect of the back adhesive. This will further affect the firmness of the ceramic tile adhesion, and the risk of hollowing and falling off in the later stage will increase significantly.

Misunderstanding 3: Not treating impurities on the back of ceramic tiles

During the production, transportation, and storage of ceramic tiles, their backs are prone to adhering to impurities such as dust, oil stains, and mold release agents. These impurities may seem insignificant, but they have a serious impact on the bonding effect of the ceramic tile back adhesive. If the impurities on the back of the ceramic tile are not thoroughly cleaned before applying the back adhesive, the impurities will form an isolation layer between the back of the ceramic tile and the back adhesive. This isolation layer will greatly reduce the actual bonding area between the ceramic tile back adhesive and the back of the ceramic tile, lowering the bonding strength. Over time, under the influence of environmental factors (such as temperature changes and humidity fluctuations) and external forces, the bonding force between the ceramic tile and the back adhesive will further weaken, greatly increasing the probability of tile hollowing. In severe cases, it may cause the ceramic tile to fall off directly, affecting the quality and service life of the decoration project. Therefore, before construction, it is necessary to use special cleaning agents and tools to thoroughly remove the impurities on the back of the ceramic tile to ensure that the back of the ceramic tile is dry and clean.

Misunderstanding 4: Reusing leftover back adhesive and stirring with water

During the construction process, there may sometimes be leftover ceramic tile back adhesive. Some operators, in order to save materials, will keep the leftover back adhesive and mix it with water and new ceramic tile back adhesive when using it again. However, in reality, the active ingredients inside the well-stirred ceramic tile back adhesive have undergone a chemical reaction during storage, forming a specific colloidal structure. Adding water for stirring at this time can, to a certain extent, change the operational performance of the back adhesive, restoring its good fluidity and facilitating construction. However, it will destroy the formed colloidal structure, resulting in a decrease in the concentration of the active ingredients in the back adhesive and a significant drop in bonding performance. Using this kind of back adhesive that has been stirred with water for the second time to paste ceramic tiles will lead to insufficient bonding strength in the later stage. The tiles are prone to hollowing and loosening, which cannot meet the requirements of long-term use. In the end, rework is still needed, which instead causes greater material waste and construction delay.

Misunderstanding 5: Randomly adding other substances to the ceramic tile back adhesive

The formula of the ceramic tile back adhesive has undergone strict scientific proportioning and optimization. The various components interact and cooperate with each other to ensure that it has excellent bonding performance and stability. During use, it is strictly forbidden to dilute the ceramic tile back adhesive with water, and it is also not allowed to add any other substances except the white sand provided in the product packaging bucket, such as cement, sand, additives of other brands, etc. Randomly adding these substances will completely change the proportion and chemical properties of each component in the ceramic tile back adhesive, destroy its internal structure, and make the quality of the back adhesive unguaranteed. The back adhesive with foreign substances added will have a greatly reduced bonding effect. When pasting ceramic tiles, problems such as hollowing and peeling are likely to occur, which seriously affects the quality of the decoration project and may even cause safety issues, bringing unnecessary losses to users.

Misunderstanding 6: Ignoring the construction environment temperature and constructing randomly in winter

The construction effect of ceramic tile back adhesive is greatly affected by the ambient temperature, and its suitable construction ambient temperature range is 5 to 35 degrees Celsius. During winter construction, due to the low temperature, if attention is not paid to anti-freezing measures and construction is carried out randomly in a low-temperature environment, the performance of the ceramic tile back adhesive will be seriously affected. When the ambient temperature is below 5 degrees Celsius, the water in the back adhesive may freeze, causing the back adhesive to be frostbitten, destroying its colloidal structure, and making it lose its original bonding performance. Even if the temperature rises later, the performance of the back adhesive cannot be restored, and the firmness of the ceramic tile adhesion cannot be guaranteed. In addition, the newly constructed ceramic tile back adhesive material should avoid being exposed to water within 24 hours to prevent water penetration from affecting the curing effect of the back adhesive and reducing the bonding strength. During summer construction, due to the high temperature and strong sun exposure, the newly constructed back adhesive will lose its effectiveness due to the rapid evaporation of water, failing to form a stable bonding layer, and may even develop cracks, affecting the bonding quality of the ceramic tiles. Therefore, during the construction process, it is necessary to pay close attention to changes in the ambient temperature and take corresponding protective measures according to the climate characteristics of different seasons to ensure the construction quality.

The above are the misunderstandings that need to be avoided in the use of ceramic tile back adhesive, explained by Shandong ceramic tile back adhesive manufacturers based on years of production and construction experience. It is hoped that the majority of decoration constructors and relevant practitioners will attach great importance to it and operate in strict accordance with the usage specifications of ceramic tile back adhesive to ensure the quality and safety of the ceramic tile bonding project. If you want to know more about the knowledge and usage skills of ceramic tile back adhesive, you are welcome to pay more attention to our website. We will update the relevant content regularly to provide you with more professional and practical guidance on the use of decoration materials.