In tile laying construction, the correct use and protection of tile back adhesive are directly related to the final laying quality. Many novice construction workers often fail to grasp the details properly, and especially when the construction period is tight and manpower is insufficient, they easily omit key protection steps, laying hidden dangers for subsequent construction. Among them, the dust-proof protection during the drying stage after applying one-component tile back adhesive is an easily overlooked but crucial link.

Why is the protection work in tile back adhesive construction indispensable? The environment of the construction site is complex, and dust often floats around. If the tiles coated with back adhesive are exposed to such an environment, the dust adhering to the surface of the back adhesive will form an isolation layer. This isolation layer will seriously damage the bonding performance between the back adhesive and the tile adhesive, leading to problems such as hollowing and falling off after subsequent tile laying, and affecting the firmness and service life of the tile laying. Therefore, doing a good job in back adhesive protection is a necessary prerequisite for ensuring construction quality.

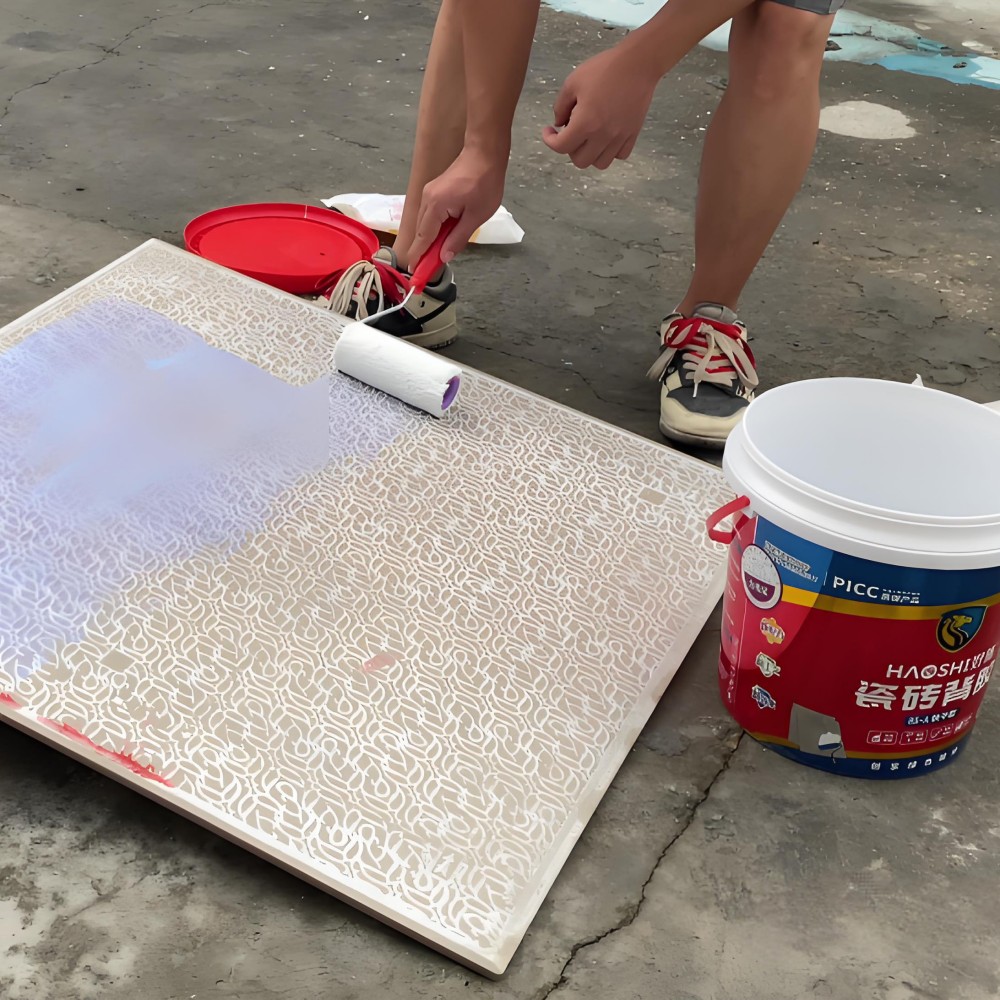

So, how to specifically do a good job in the protection of tile back adhesive construction? Firstly, the tiles coated with back adhesive should be properly shielded. Clean waterproof cloth, plastic film and other materials can be used for covering to ensure that the tile surface does not directly contact the dust in the air. Secondly, clear and eye-catching protection signs must be set up. For example, warning signs such as "No Touching" and "No Treading" should be hung around the shield to remind construction personnel to pay attention and avoid damage to the back adhesive or dust contamination due to accidental touching.

If the back adhesive is accidentally stained with dust, how to deal with it? Construction personnel need to take different measures according to the degree of dust contamination. When there is little dust, prepare a clean towel, dip it in a small amount of clean water, and wipe the dust on the surface of the back adhesive with gentle force. Be careful not to use too much force to damage the back adhesive coating. After wiping, wait for the back adhesive to dry completely before carrying out the subsequent tile adhesive construction. However, if the dust contamination is serious and the dust has penetrated into the back adhesive and is difficult to remove by wiping, then this batch of tiles may need to be discarded. If they are used forcibly, the bonding effect between the tiles and the base layer will be seriously affected, and quality accidents such as tile falling off are likely to occur in the later period.

In addition, choosing high-quality tile back adhesive and using it correctly is also an important link to ensure construction quality. Shandong Yongqiang Chemical Tile Back Adhesive Manufacturer suggests that the tiles rolled with back adhesive should complete the subsequent construction within 72 hours to avoid the back adhesive being exposed to the air for a long time and reducing its bonding performance. Construction personnel need to pay attention to every detail and strictly follow the specifications to do a good job in protection and construction operations, so as to ensure the quality and stability of the tile laying project.