Detailed Explanation of Common Misunderstandings in the Use of Tile Adhesive

In the construction of tile laying, the correct use of tile adhesive is a key link to ensure the quality of laying. However, in actual operation, many people fall into many misunderstandings in using tile adhesive due to their lack of understanding of its characteristics, which not only affects the construction effect but also may lead to problems such as hollowing and falling off of tiles in the later period. The following is a detailed analysis of several common misunderstandings about tile adhesive.

Misunderstanding 1: Adding Cement to Tile Adhesive

Tile adhesive is a product developed and formulated professionally, and the proportion of its various components is carefully calculated. This ensures that when used, the slurry prepared by adding water in the specified proportion has good elasticity, so that the tiles have strong stability and good effect after being laid.

If cement or other materials are added to the tile adhesive without authorization, the scientific proportion structure of the tile adhesive itself will be directly destroyed. During the subsequent hardening process, this damaged proportion will greatly increase the shrinkage degree of the paste. The stress generated by the shrinkage will cause the paste to crack. As time goes by, the cracking problem will further affect the bonding between the tiles and the base layer, eventually leading to hollowing of the wall or floor tiles, and even falling off of the tiles in severe cases, which greatly affects the service life and overall appearance of the tile laying.

Then, how to judge whether cement has been illegally added to the tile adhesive? Generally, after cement hardens, the color of its surface is relatively dark. By observing the color of the tile adhesive after hardening, we can initially judge whether there is illegal addition of cement.

Misunderstanding 2: Scraping Adhesive in Too Large an Area at One Time, Causing the Tile Adhesive Surface to Dry and Harden

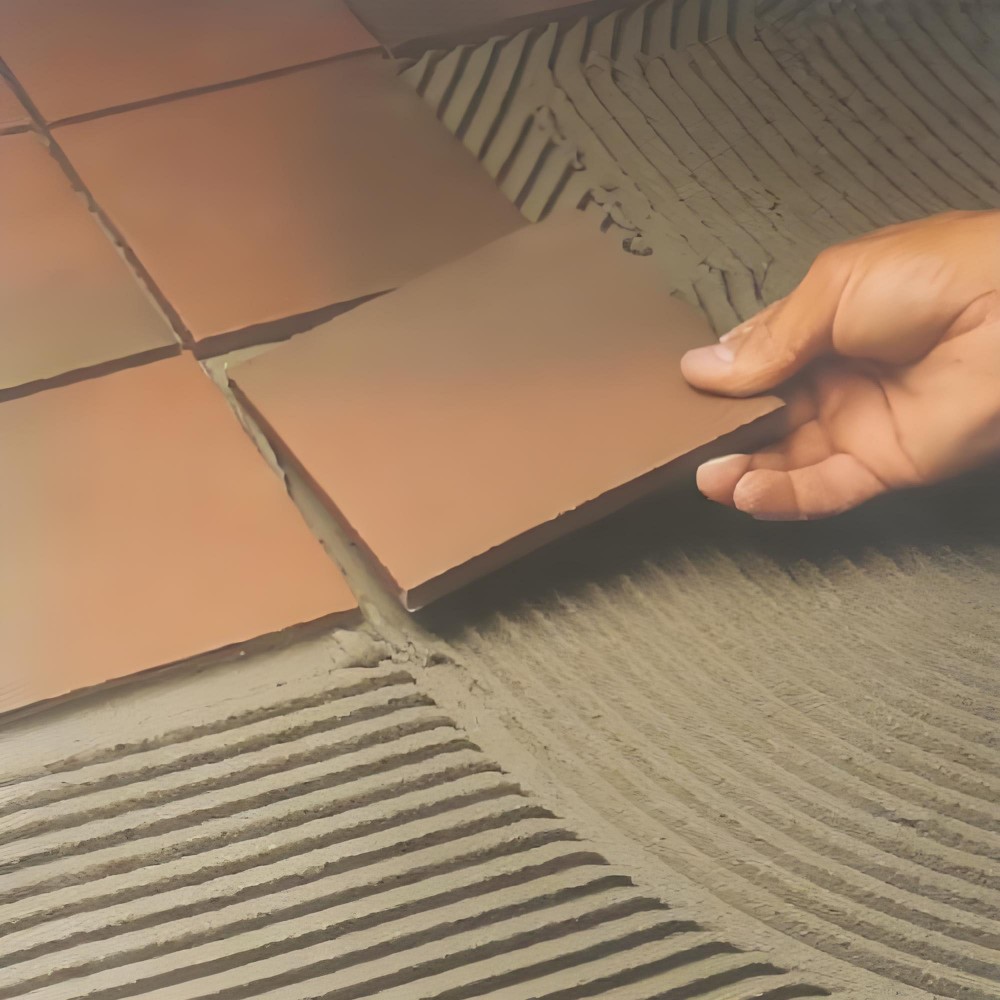

In the process of tile laying construction, the operation method of the adhesive scraping link also has an important impact on the construction quality. Especially when constructing outdoors, if it is a dry and windy day, the air circulation speed is fast and the water evaporation is rapid. At this time, if the area of adhesive scraped at one time is too large, during the subsequent tile laying process, due to the need for a certain time for construction, the surface of the scraped tile adhesive will become dry and hard due to the rapid evaporation of water.

This dry and hard tile adhesive surface will lose its original bonding performance. When laying tiles, the tiles cannot be fully bonded with the tile adhesive, which is prone to the situation that the tiles and the adhesive layer are not closely attached, thus causing problems such as hollowing and falling off of the tiles after laying, which seriously affects the construction quality and the stability of the tiles after laying.

To avoid such problems, when scraping the adhesive, a serrated scraper should be used to evenly scrape the adhesive paste on the working surface, and the area of adhesive scraping should be controlled. Usually, the area of adhesive scraping in each construction stage is about 1 square meter to ensure that the tile laying operation can be carried out in time after scraping. At the same time, if the construction is carried out in a dry outdoor climate, the wall should be wetted in advance. By increasing the humidity of the wall surface, the evaporation rate of water in the tile adhesive is slowed down, ensuring that the tile adhesive always maintains a good bonding state when laying tiles.

Misunderstanding 3: Using Tile Adhesive to Fill Joints

The designed use of tile adhesive is clear. It is only suitable for being coated on the back of tiles to play the role of bonding the tiles and the base layer, and does not have the function and performance of joint filling.

If tile adhesive is incorrectly used for joint filling, when the tiles expand and contract due to factors such as temperature changes during use, the gaps blocked by the tile adhesive cannot provide enough space for the shrinkage of the tiles, which will generate extrusion stress on the tiles. This stress will damage the bonding structure between the tiles and the base layer, which is prone to cause hollowing of the tiles. Over time, the hollowing problem will continue to worsen, eventually leading to the falling off of the tiles, which not only affects the normal use of the tiles but also increases the maintenance cost and difficulty.

Therefore, special joint filling products are needed for tile joint filling. Such products have good elasticity and anti-shrinkage performance, can adapt to the thermal expansion and contraction of tiles, effectively fill the tile gaps, and at the same time can play the role of waterproof and anti-fouling, ensuring the appearance and durability of the tile gaps.

The above is a detailed analysis of the common misunderstandings in the use of tile adhesive. Mastering the correct method of using tile adhesive can effectively improve the quality of tile laying and avoid various problems in the later period. If you want to know more about tile adhesive in Shandong, welcome to pay more attention to our website, and we will continue to share more professional and practical content for you.