With the improvement of people's living standards, more and more families are choosing high-quality vitrified tiles for home decoration. However, the characteristics of vitrified tiles, such as dense surface and extremely low water absorption, bring difficulties to the tiling work - the adhesion of traditional cement mortar is completely unable to meet its needs. If vitrified tiles are only paved with cement mortar, they may seem stable in the short term, but after temperature changes, humidity fluctuations or slight daily vibrations, they are prone to hollowing, and in severe cases, even the entire tile may fall off, which not only affects the beauty of the home but also poses potential safety hazards.

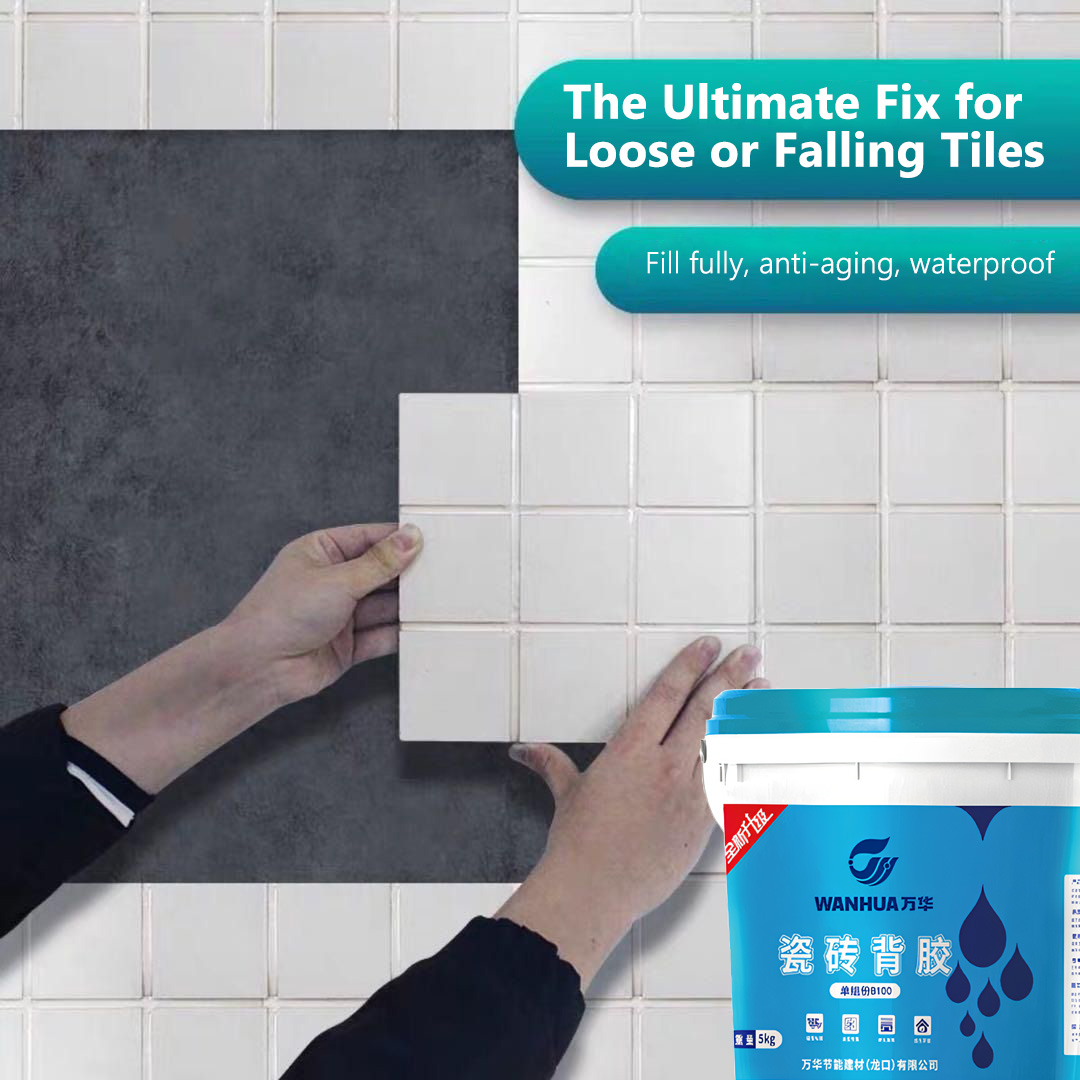

At this point, Shandong Tile Back Adhesive becomes a key product to solve this problem. It is like a "strong double-sided tape" between the tiles and the bonding material, which can greatly improve the bonding strength between the vitrified tiles and the bonding layer, and fundamentally eliminate the problems of hollowing and tile falling. More importantly, it is not limited by the size of the tiles. Whether it is small-sized wall tiles or large-sized floor tiles, it can be easily adapted, which greatly simplifies the construction process and saves a lot of time and energy for decoration workers.

However, to make Shandong Tile Back Adhesive fully play its role, the correct usage method is crucial, and no step can be taken lightly:

- Cleaning Treatment: Before construction, the top priority is to clean the back of the tiles and the wall base. The back of the tiles usually has residual release powder, which will seriously affect the bonding effect of the back adhesive. It must be wiped repeatedly with a damp cloth or thoroughly removed with a special tool; the wall base must also be kept clean and solid. If there is oil or wax, it can be cleaned with a detergent. If there is dust, it must be cleaned with a vacuum cleaner or a brush to ensure that no impurities affect the bonding.

- Environment Control: The construction environment has a significant impact on the effect of the back adhesive. A relatively dry environment should be selected, requiring the relative air humidity to be less than 70%. If the environment is too humid, the drying speed of the back adhesive will slow down, which may lead to unstable bonding; the construction temperature should be controlled between 0℃ and 35℃. Too low a temperature will slow down the curing speed of the back adhesive, and too high a temperature may cause the back adhesive to dry and set too quickly, affecting the bonding performance. At the same time, the construction area should be well-ventilated to help the back adhesive dry normally.

- Brushing Operation: After opening the tile back adhesive, first stir it gently with a stirring rod to avoid affecting the effect due to sedimentation of components. Then dip the back adhesive with a roller or a brush and apply it evenly on the back of the tiles or stones. During the brushing process, care should be taken to avoid missing any part and ensure that every part is covered with the back adhesive. The brushing thickness should be strictly controlled at about 0.5mm. Too thick a layer will prolong the drying time and may cause the tiles to fall off later due to incomplete curing inside; if the base surface is smooth and has low water absorption (such as some glass curtain wall bases and polished stone bases), it is recommended to apply a layer of back adhesive on the base surface to be bonded to further enhance the bonding force.

- Drying Stage: Tiles (or stones) coated with back adhesive cannot be paved immediately. They need to be placed with their backs facing up for natural drying. The purpose of drying is to allow the moisture in the back adhesive to evaporate gradually and form a film with adhesive force. This process requires patience and cannot be rushed.

- Paving Timing: The key criterion for judging whether the tiles can be paved is "sticky but not wet to the touch" - touch the back adhesive on the back of the tiles with your hand. If it feels sticky but does not stick to your hand, the back adhesive has reached the best bonding state. At this time, the tiles can be accurately paved on the pre-treated walls or floors, and gently pressed after paving to ensure that the tiles are closely attached to the base.

The above is the practical usage knowledge shared by Shandong tile back adhesive manufacturers. Mastering these methods can make the vitrified tile paving more stable and durable. If you want to know more professional knowledge about tile back adhesive, you are welcome to pay more attention to the official website of the manufacturer to obtain the latest and most comprehensive industry information.